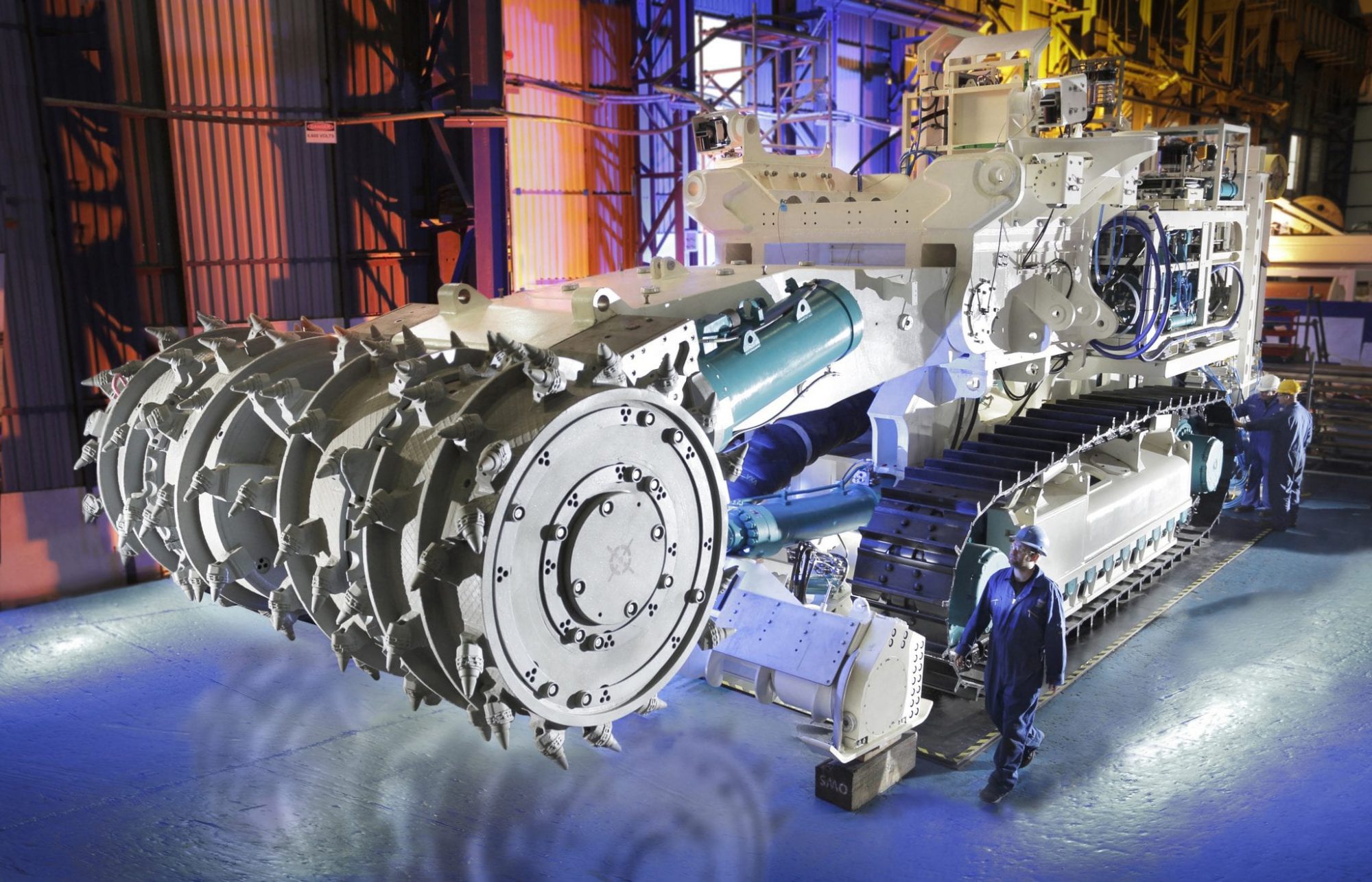

May 2015: Our Mining team saw another major milestone in the first quarter of 2015 as the commissioning of the third and final of the Seafloor Production Tools (SPT), the Auxiliary Cutter, began.

The three SPTs have been in assembly in SMD’s main Wallsend heavy equipment assembly hall, known as the Turbinia Works, throughout 2014. The launch and recovery equipment was assembled at various locations in Norway, Poland and Korea and is already complete.

Nautilus’ CEO, Mike Johnston said “We are very excited that commissioning of the final of the three SPTs has begun. With the Bulk Cutter and the Collecting Machine having already begun Factory Acceptance Testing and now with the Auxiliary Cutter underway, we are on track to complete this testing phase and take delivery of the three SPTs in Q4 2015.”

SMD’s Managing Director, Mike Jones commented “This is always an important and delicate phase, particularly when developing such large scale and high power technology. The experience from the first two SPTs will be a great help in this. We look forward to their despatch for wet testing later this year.”

So How Will They Work?

The excavation and collection of mineralised material has been split into three individual tasks, with each carried out by a different SPT. The Auxiliary Cutter is designed as the pioneering tool which prepares the rugged sea bed for the more powerful Bulk Cutter. These two tools gather the excavated material; the third, the Collecting Machine, will collect the cut material by drawing it in as seawater slurry with internal pumps and pushing it through a flexible pipe to the subsea pump and on to the vessel via the Riser and Lifting System.

The Auxiliary Cutter weighs in at 250 tonnes. It is a preparatory machine that deals with rough terrain and creates benches for the other SPTs to work on. It will operate on tracks with spud assistance and has a boom mounted cutting head for flexibility.

The Bulk Cutter is the heaviest of the three SPTs, weighing 310 tonnes when fully assembled. It is designed to be the high productivity machine responsible for the bulk of production.

The Collecting Machine is the lightest of the three SPTs, weighing 200 tonnes when fully assembled. It is designed to collect material cut from the seafloor by drawing it in as seawater slurry with internal pumps and pushing it through a flexible pipe to the Riser and Lifting System and onto the vessel.

What will they mine?

The vehicles will be used to mine polymetallic sulphides, rich in copper and gold, at the Solwara 1 deposit which sits on the seafloor at a water depth of some 1600 metres, off the coast of Papua New Guinea. The mine site boasts a copper grade of approximately 7%, which is significantly higher than land-based copper mines, where the copper grade today averages typically 0.6%. In addition, gold grades of well over 20 g/tonne have been recorded in some intercepts at Solwara 1 and the average grade is approximately 6 g/tonne.