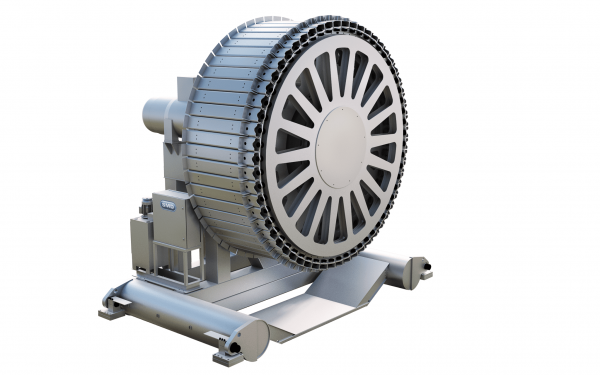

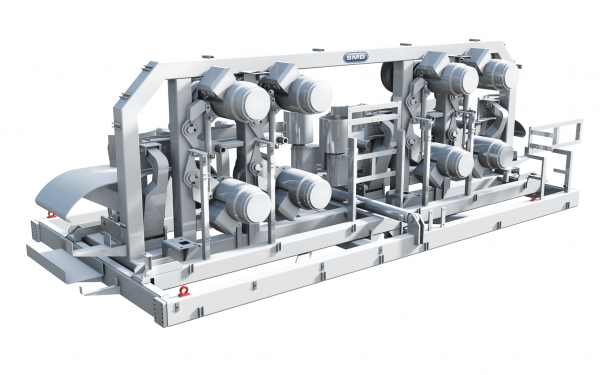

We offer a range of Cable Drum Engines (CDE’s) including a unique knife-free Self-Fleeting Drum, which allows for flexible cable spacing, increasing the lay speed and reducing the risk of cable damage during lay operations.

SMD drum engine designs are lower weight compared to equivalent designs and are suitable for both cable laying and repair operations. Designs include variable speed AC transmission with integral hydraulic service pack and hydraulic drive transmission options.

Our CDE’s have reduced rolling resistance compared with conventional drum engines, which improves slow speed control and low tension render performance.